We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog

-

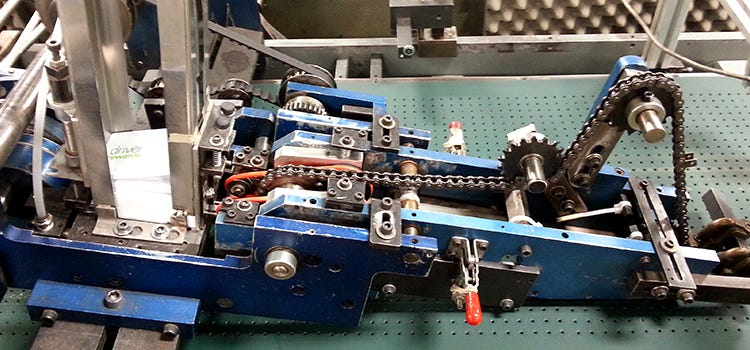

Posted: September 11, 2020Spiral-Tech® Replaces power transmission flat drive belt on Roll Back Stands. Features & Benefits: Pin splice assembly minimum downtime No equipment disassembly Carboxylated nitril...Read more »

-

Posted: September 04, 2020Features & Benefits: MIR stocks the OEM equivalent belts for immediate delivery MIR produces molded/seamless belts Larger spiked profiles are available USDA/FDA compliant compounds and constructi...Read more »

-

Posted: November 20, 2019Categories: ResourcesApplications lines at your mailing or lettershop facility convey thousands of letters, packages and coupons to meet ambitious production demands. But in the midst of these impressive feats of conveyan...Read more »

-

Posted: November 20, 2019Categories: ResourcesWhen PVC and laminated materials arrive at your facility, specialized equipment must precisely and efficiently cut the materials into cards, which are then personalized and packaged for end uses acros...Read more »

-

Posted: September 05, 2019Categories: NewsSt. Louis, MO – MIR is excited to announce the acquisition of another great company in the belting industry, Splawn Belting (“Splawn”). The acquisition of Splawn is MIR&rsq...Read more »

-

Posted: September 04, 2019Categories: Case StudyChronic belt cutting causes costly replacements These automotive hood lines had traditionally moved face-up parts from press to press with no issue. But newly introducedRead more »

-

Posted: July 15, 2019Categories: Case StudyFolding rail belt damage caused costly downtime At this Corrugated Box plant, two common problems created issues with the folding rail belts: Mechanical lace pull out andRead more »

-

Posted: July 15, 2019Categories: Case StudyX-ray belt stretching risked sanitation The facility manager noticed the X-ray belt continually stretched out at the pin holes, causing disengagement and frequentRead more »

-

Posted: July 15, 2019Categories: Case StudyIndexing application mis-tracking causes unforeseen downtime On this indexing equipment, the V-guide was detaching due to small pulley diameter, causing the belt toRead more »

-

Posted: July 15, 2019High conductivity causes downtime on unwind and rewind belt The unwind and rewind application at this facility faced an issue with high conductivity. This occurs when twoRead more »